In the realm of drilling operations, precision, efficiency, and safety are paramount. One method that stands out for its effectiveness and versatility is kelly drilling.

This comprehensive guide will delve into the intricacies of kelly drilling, shedding light on its various aspects, applications, and importance in the field.

What Is Kelly Drilling

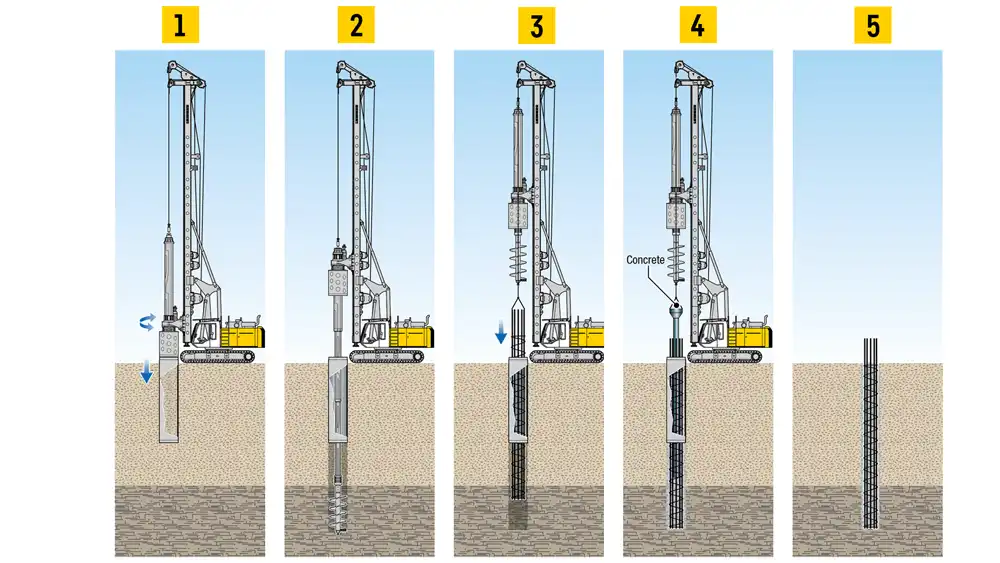

Kelly drilling is a method used in the realm of drilling operations, particularly in industries such as oil and gas exploration, mining, geotechnical engineering, and environmental remediation. This technique involves the use of a specialized tool called a kelly, which is a cylindrical pipe designed to transmit torque from the surface to the drill bit deep underground.

The process begins with the insertion of the kelly into the drill string, a series of interconnected pipes that extend from the drilling rig to the bottom of the borehole. The kelly is connected to the rotary table, which provides the necessary rotational force to drive the drill bit into the earth.

The Importance of Kelly Drilling

Kelly drilling holds profound significance in the realm of drilling operations, serving as a cornerstone for various industries and applications. Its importance stems from several key factors that highlight its indispensability in modern drilling practices.

First and foremost, kelly drilling provides a vital means of accessing subsurface resources, such as oil, gas, minerals, and water. By efficiently penetrating through geological formations, kelly drilling enables the extraction and exploitation of these valuable resources, supporting essential industries and meeting global energy and resource demands.

Moreover, the versatility of kelly drilling makes it well-suited for a wide range of drilling scenarios and environments. Whether drilling in soft soils, hard rock formations, or challenging terrains, kelly drilling offers the necessary torque, precision, and control to navigate through various geological strata with ease.

Additionally, the efficiency of kelly drilling plays a crucial role in optimizing drilling operations and minimizing costs. By streamlining the drilling process and maximizing productivity, kelly drilling helps companies achieve their drilling objectives in a timely and cost-effective manner, enhancing overall project profitability and competitiveness.

Furthermore, kelly drilling contributes to safety and environmental sustainability in drilling operations. Through rigorous safety protocols, environmental protection measures, and adherence to regulatory standards, kelly drilling operations prioritize the well-being of personnel and minimize their impact on the environment, ensuring responsible and sustainable drilling practices.

Components of Kelly Drilling

Kelly drilling comprises several essential components that work in tandem to facilitate efficient and effective drilling operations. Understanding these components is crucial for optimizing performance, ensuring safety, and achieving drilling objectives.

Let’s delve into the key components of kelly drilling:

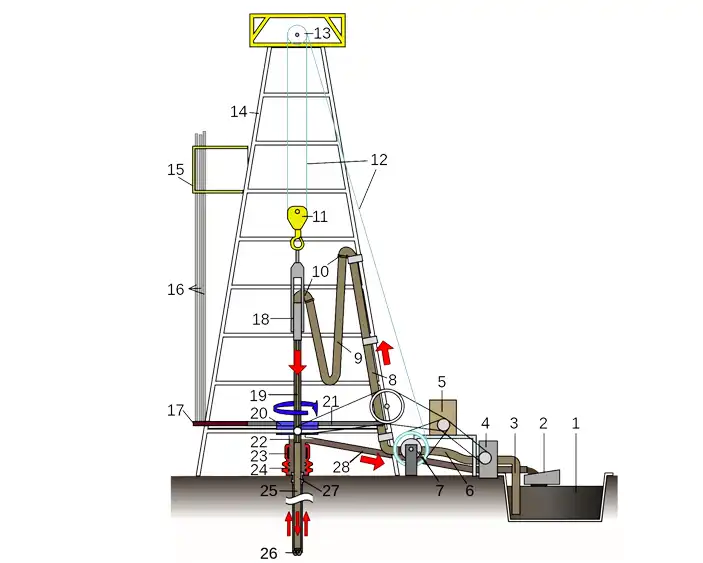

- Kelly Bar: The kelly bar is a cylindrical pipe that serves as the primary conduit for transmitting torque from the surface to the drill bit deep within the borehole. It connects to the rotary table and provides rotational force to the drill string and attached bit.

- Swivel: The swivel is a pivotal component that allows the kelly to rotate freely while maintaining a sealed connection with the drill string. It prevents the transfer of drilling fluid and pressure to the surface, ensuring smooth and uninterrupted drilling operations.

- Rotary Table: The rotary table is a heavy-duty mechanism mounted on the drilling rig’s platform. It serves as the interface between the surface equipment and the drill string, providing the necessary rotational energy to drive the kelly and drill bit into the subsurface formations.

- Drill String: The drill string is a series of interconnected pipes that extend from the surface to the bottom of the borehole. It comprises various components, including drill pipes, collars, and stabilizers, that transmit rotational force and weight to the drill bit, enabling penetration through geological formations.

- Drill Bit: The drill bit is the cutting tool attached to the bottom of the drill string. It comes in various designs and materials optimized for specific drilling conditions and formations. The drill bit rotates and cuts into the rock or soil, creating the borehole as it advances deeper into the earth.

- Kelly Bushing: The kelly bushing is a component mounted on the rotary table that provides support and guidance to the kelly as it rotates. It helps maintain alignment between the kelly and the drill string, preventing excessive wear and ensuring smooth drilling operations.

- Kelly Spinner: The kelly spinner is a device used to facilitate the connection and disconnection of the kelly from the drill string. It applies torque to the kelly, allowing it to thread into or out of the drill string quickly and efficiently during tripping operations.

Understanding the functions and interactions of these components is essential for optimizing kelly drilling operations, ensuring safety, and achieving success in various drilling applications and environments.

Techniques for Success

Mastering the art of kelly drilling requires employing proven techniques that maximize efficiency and minimize risks. Techniques such as controlled rotation speed, proper weight on bit, and mud circulation play vital roles in achieving optimal results.

Innovations Driving Progress

The field of kelly drilling continues to evolve, thanks to ongoing innovations aimed at enhancing efficiency, safety, and environmental sustainability. Innovations like automated drilling systems, advanced mud recycling technologies, and intelligent drilling software are revolutionizing the industry.

Kelly Drilling Applications

Kelly drilling finds applications across various industries, ranging from oil and gas exploration to geotechnical engineering.

Let’s explore some of the key sectors where kelly drilling plays a pivotal role.

Oil and Gas Exploration

In the oil and gas industry, kelly drilling is indispensable for accessing underground reservoirs and extracting hydrocarbon resources. It enables companies to drill wells efficiently and economically, supporting global energy needs.

Geotechnical Engineering

In geotechnical engineering, kelly drilling is used for site investigation, foundation construction, and soil sampling. Its ability to penetrate different soil and rock formations makes it a valuable tool for assessing ground conditions and designing structures.

Environmental Remediation

Kelly drilling plays a crucial role in environmental remediation projects, such as groundwater monitoring and contaminant cleanup. Its precision and versatility make it ideal for accessing subsurface layers and implementing remediation strategies.

Mining Operations

In the mining industry, kelly drilling is utilized for exploration, delineation of ore bodies, and extraction of mineral resources. Its ability to penetrate hard rock formations efficiently makes it a preferred method for mining companies worldwide.

FAQs

What is the role of the kelly in kelly drilling?

The kelly serves as a conduit for transmitting torque from the rotary table to the drill string, enabling the rotation of the drill bit for penetration into the subsurface formations.

How does kelly drilling differ from other drilling methods?

Unlike methods such as rotary drilling, kelly drilling utilizes a kelly bar to transmit torque, offering greater precision and control over the drilling process.

What safety measures are in place to protect workers during kelly drilling operations?

Safety measures include comprehensive risk assessments, regular equipment inspections, personal protective equipment (PPE) requirements, and emergency response protocols to mitigate potential hazards.

What are some environmental considerations associated with kelly drilling?

Environmental considerations include minimizing disturbance to sensitive ecosystems, preventing contamination of groundwater sources, and responsibly managing drilling waste and emissions.

How do advancements in technology impact kelly drilling operations?

Technological advancements such as automated drilling systems, real-time data monitoring, and predictive analytics enhance efficiency, safety, and environmental sustainability in kelly drilling operations.

What are the key factors to consider when selecting a kelly drilling contractor?

Factors to consider include the contractor’s experience, track record of safety and regulatory compliance, availability of specialized equipment, and commitment to environmental stewardship.

Conclusion

Kelly drilling stands as a testament to human ingenuity and innovation in the realm of drilling technology. Its versatility, efficiency, and reliability make it a cornerstone of various industries, from oil and gas exploration to environmental remediation. By prioritizing safety, environmental responsibility, and continuous improvement, the industry ensures that kelly drilling remains a sustainable and indispensable method for accessing the earth’s resources.