Unveiling the intricate mechanisms behind hydraulic tensioners is akin to deciphering the inner workings of a well-oiled machine. These crucial components play a pivotal role in maintaining tension within various systems, ensuring optimal performance and longevity.

In this detailed guide, we delve deep into the realm of hydraulic tensioners, exploring their functionality, applications, and significance across industries.

What Are Hydraulic Tensioners

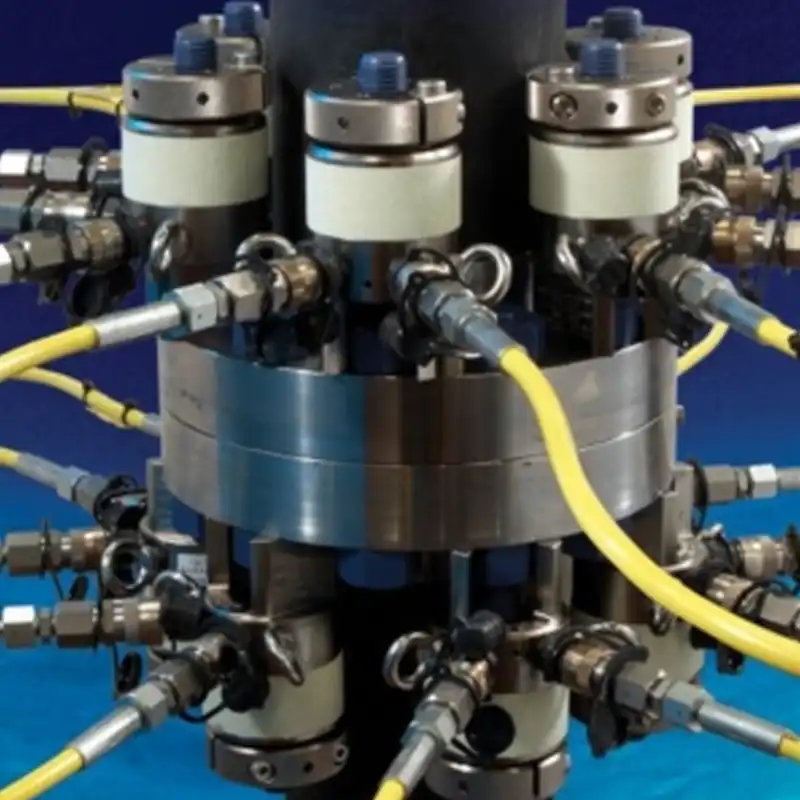

Hydraulic tensioners are mechanical devices used to maintain proper tension in various components of machinery and equipment. They operate by utilizing hydraulic fluid to exert controlled force, ensuring that belts, chains, or other tensioned elements remain taut and functional.

These tensioners are commonly employed in automotive timing systems, industrial machinery, and aerospace applications, where precise tensioning is crucial for optimal performance and reliability. With their ability to dynamically adjust tension levels and withstand varying operational conditions, hydraulic tensioners play a vital role in ensuring the smooth and efficient operation of mechanical systems.

The Role of Hydraulic Tensioners

The role of hydraulic tensioners is paramount in maintaining the integrity and functionality of various mechanical systems. These devices serve as guardians of tension, ensuring that critical components such as belts, chains, and pulleys remain appropriately taut.

By exerting controlled pressure through hydraulic fluid, tensioners eliminate slack and prevent potential issues such as slipping, misalignment, or premature wear.

In automotive applications, hydraulic tensioners play a vital role in timing belt systems, synchronizing engine components and preventing catastrophic failures.

Similarly, in industrial machinery and aerospace applications, these tensioners contribute to operational efficiency and reliability by ensuring smooth and uninterrupted motion.

How Hydraulic Tensioners Work

Hydraulic tensioners operate on a sophisticated mechanism that utilizes hydraulic fluid to maintain precise tension levels within mechanical systems.

Here’s a detailed explanation of how they work:

Hydraulic Fluid Transmission:

Hydraulic tensioners rely on hydraulic fluid as the driving force behind their operation. This fluid is contained within a reservoir and is pressurized by external means, such as a hydraulic pump or engine-driven system.

Piston Actuation:

Central to the functioning of hydraulic tensioners is a piston mechanism. When hydraulic pressure increases within the system, it acts upon the piston, causing it to extend outward. This extension applies tension to the system’s components, such as belts or chains.

Spring Assistance:

To ensure consistent tension levels, hydraulic tensioners often incorporate springs into their design. These springs provide additional support, maintaining tension even in situations where hydraulic pressure fluctuates.

Continuous Adjustment:

Hydraulic tensioners are designed for dynamic adjustability, allowing them to respond in real-time to changes in operating conditions. As hydraulic pressure varies, the tensioner adjusts accordingly, ensuring optimal tension levels at all times.

In essence, hydraulic tensioners work by harnessing the power of hydraulic fluid to exert controlled force on mechanical components, thereby maintaining tension and preventing slackness. This dynamic adjustability and precise tension regulation make them essential components in a wide range of applications, from automotive engines to industrial machinery.

Hydraulic Tensioner Applications

Hydraulic tensioners find diverse applications across various industries, where they play a crucial role in ensuring the smooth operation and reliability of mechanical systems. Here are some common applications:

Automotive Sector:

In the automotive industry, hydraulic tensioners are integral components of timing belt and chain systems. They help synchronize the movement of engine components, such as camshafts and crankshafts, ensuring precise timing and optimal engine performance. By maintaining proper tension, hydraulic tensioners prevent slackness in belts or chains, reducing the risk of timing errors and engine damage.

Industrial Machinery:

Within industrial settings, hydraulic tensioners are utilized in a wide range of machinery and equipment. They play key roles in conveyor systems, pulley arrangements, and other mechanical setups where maintaining tension is critical for smooth operation. By ensuring that belts, chains, or other tensioned components remain taut, hydraulic tensioners enhance productivity and minimize downtime.

Aerospace and Marine Engineering:

The aerospace and marine industries demand stringent performance standards, making hydraulic tensioners invaluable components in critical applications. From aircraft engines to ship propulsion systems, hydraulic tensioners help maintain precise tension in timing mechanisms, drive belts, and other vital components. Their reliability and ability to operate under extreme conditions make them indispensable in these high-stakes environments.

Construction and Heavy Machinery:

Hydraulic tensioners play a vital role in construction equipment and heavy machinery, where they are used to maintain tension in drive belts, chains, and hydraulic hoses. Whether in excavators, bulldozers, or cranes, hydraulic tensioners ensure that moving parts operate smoothly and efficiently, contributing to overall productivity and safety on construction sites.

Power Generation:

In power generation facilities, hydraulic tensioners are utilized in turbine systems, generators, and other equipment where precise tensioning is essential for optimal performance. By preventing slackness in drive belts or chains, hydraulic tensioners help maximize energy efficiency and minimize the risk of mechanical failures, ensuring continuous power supply.

FAQs

How does a hydraulic tensioner maintain tension?

Hydraulic tensioners utilize hydraulic fluid pressure to exert controlled force, ensuring optimal tension levels within mechanical systems.

What are the benefits of hydraulic tensioners over mechanical alternatives?

Unlike mechanical tensioners, hydraulic variants offer dynamic adjustability and continuous tension regulation, enhancing efficiency and reliability.

Can hydraulic tensioners be retrofitted into existing systems?

Yes, hydraulic tensioners are designed to integrate seamlessly into various mechanical configurations, offering versatility and compatibility.

What maintenance is required for hydraulic tensioners?

Periodic inspection and fluid replenishment are essential for maintaining optimal tensioner performance, ensuring longevity and reliability.

Are hydraulic tensioners susceptible to leaks or malfunctions?

While rare, hydraulic tensioners may experience leaks or malfunctions due to wear or external factors. Regular maintenance and prompt repairs mitigate such risks.

How do environmental factors affect hydraulic tensioner performance?

Extreme temperatures or contaminants in hydraulic fluid can impact tensioner performance. Choosing appropriate fluid and conducting regular maintenance mitigate these risks.

Conclusion

In conclusion, the inner workings of hydraulic tensioners are a testament to precision engineering and innovative design. By understanding how these components operate, we gain insight into the intricate dance of forces that drive mechanical systems forward. Whether in automotive, industrial, or aerospace applications, hydraulic tensioners stand as silent sentinels, ensuring smooth operation and safeguarding against potential failures.