Concrete pump hoses are vital components in construction projects, facilitating the smooth transfer of concrete from the mixer to the desired location. However, over time, these hoses can accumulate debris, leading to reduced efficiency and potential damage. Proper cleaning is essential to ensure the longevity and performance of concrete pump hoses.

In this guide, we’ll delve into various techniques and best practices for effectively cleaning concrete pump hoses.

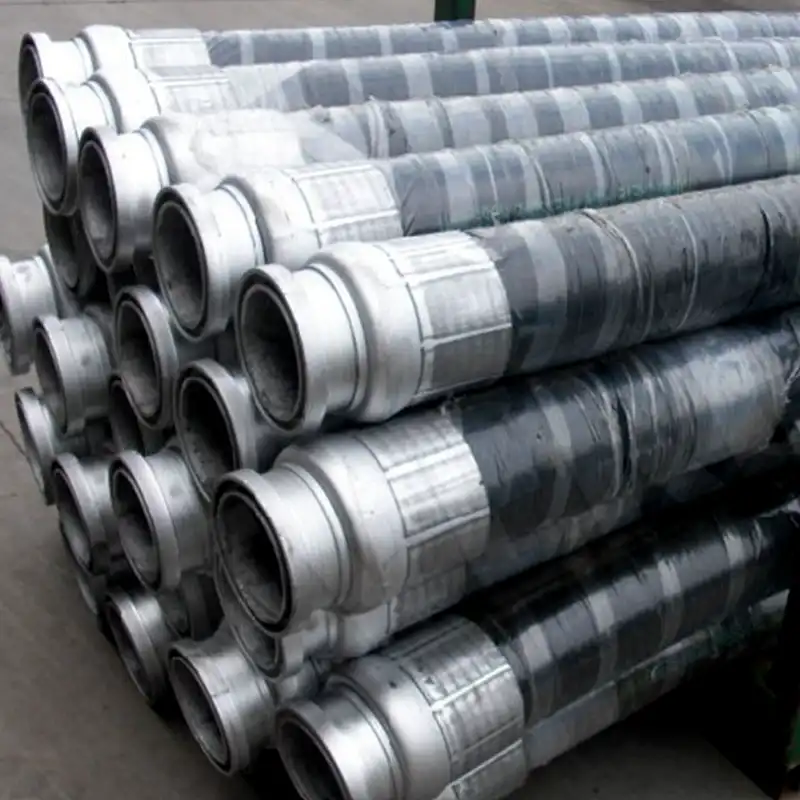

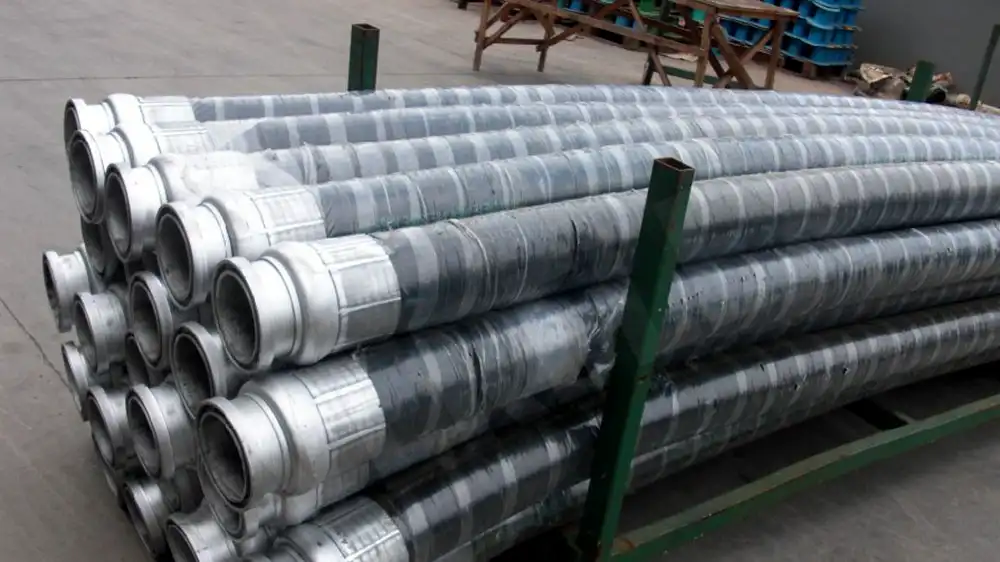

What Is Concrete Pump Hose?

Concrete pump hoses are flexible tubes used in construction projects to transport concrete from the mixer to the desired location. They are typically made of rubber or synthetic materials and are designed to withstand the high pressure generated during concrete pumping operations.

These hoses come in various lengths and diameters to accommodate different project requirements. Concrete pump hoses play a crucial role in ensuring the efficient and precise placement of concrete, contributing to the overall success of construction endeavors.

Concrete Pump Hose Cleaning

Concrete pump hose cleaning is a critical maintenance task in construction projects involving concrete pumping. This process involves removing hardened concrete, sediment, and debris from the inner surface of the hose to ensure smooth and efficient operation.

Here’s everything you need to know about cleaning concrete pump hoses:

Importance of Cleaning: Regular cleaning of concrete pump hoses is essential to prevent blockages, maintain efficiency, and prolong the lifespan of the equipment. Neglecting cleaning can lead to reduced performance, equipment damage, and safety hazards.

Methods of Cleaning: There are several methods for cleaning concrete pump hoses, including:

Mechanical Cleaning: Using brushes, scrapers, or pigs to physically remove hardened concrete and debris.

Chemical Cleaning: Utilizing specialized cleaning agents to dissolve concrete buildup and loosen debris.

High-Pressure Water Jetting: Employing powerful water streams to dislodge and flush out accumulated material.

Preventive Maintenance: In addition to regular cleaning, preventive maintenance measures can help prolong hose lifespan and minimize the need for repairs. These include:

Inspection and Monitoring: Regularly checking hoses for wear, damage, or blockages.

Proper Storage: Storing hoses in a clean, dry environment away from extreme temperatures and corrosive substances.

Training and Education: Providing operators with comprehensive training on proper handling, usage, and maintenance practices.

Safety Precautions: When cleaning concrete pump hoses, it’s essential to prioritize safety by wearing appropriate protective gear, following manufacturer guidelines, and avoiding hazardous chemicals or techniques.

Environmental Considerations: Proper disposal of wastewater and waste material generated during hose cleaning is crucial to minimize environmental impact. Follow local regulations and best practices for environmentally-friendly waste management.

Frequency of Cleaning: Concrete pump hoses should be cleaned after each use to prevent concrete buildup and maintain optimal performance. However, the frequency of cleaning may vary depending on usage, concrete composition, and environmental conditions.

Methods for Cleaning Concrete Pump Hose

Cleaning concrete pump hoses requires a systematic approach and the use of suitable equipment. Here are some effective methods for cleaning concrete pump hoses:

Mechanical Cleaning

Mechanical cleaning involves the use of brushes, scrapers, or pigs to physically remove hardened concrete and debris from the inner surface of the hose. This method is ideal for removing stubborn deposits and restoring optimal flow capacity.

Chemical Cleaning Agents

Chemical cleaning agents, such as detergents or acids, can be used to dissolve hardened concrete and loosen debris from the hose walls. However, caution must be exercised when using chemicals to avoid damage to the hose material and ensure safety.

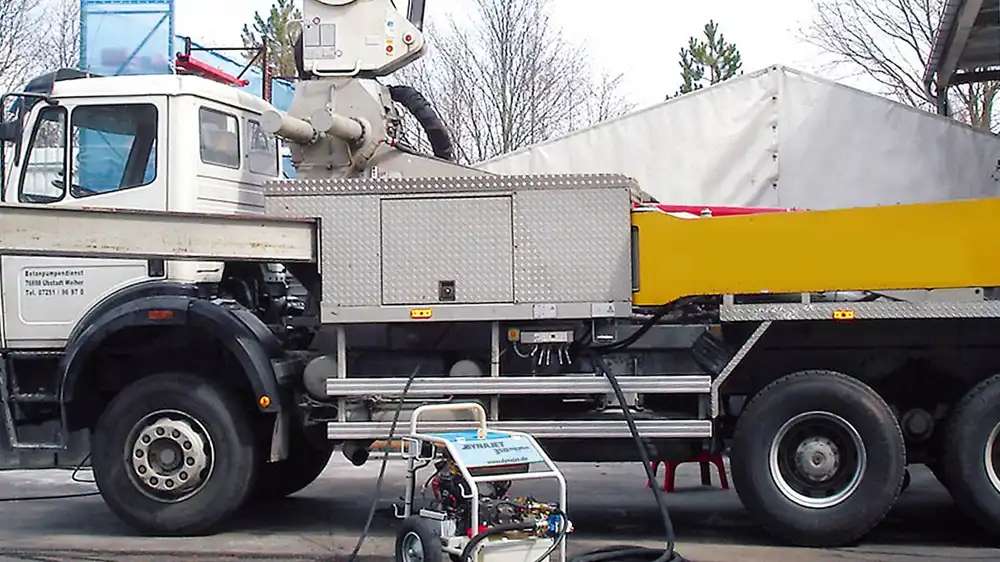

High-Pressure Water Jetting

High-pressure water jetting utilizes powerful streams of water to dislodge and flush out accumulated debris from the hose interior. This method is highly effective for cleaning hard-to-reach areas and achieving thorough cleaning results.

Maintenance Tips of Concrete Pump Hoses

Preventive maintenance plays a crucial role in ensuring the longevity and optimal performance of concrete pump hoses. By implementing proactive measures, construction professionals can minimize the risk of downtime, costly repairs, and safety hazards.

Here’s an in-depth look at preventive maintenance tips for concrete pump hoses:

Regular Inspection and Monitoring:

Conducting regular inspections of concrete pump hoses is essential for detecting signs of wear, damage, or blockages early on. Inspect the exterior and interior surfaces of the hoses for cracks, abrasions, bulges, or any abnormalities. Additionally, monitor hose condition during operation to identify potential issues before they escalate.

Proper Storage Practices:

Proper storage of concrete pump hoses is critical for preserving their integrity and preventing damage. Store hoses in a clean, dry environment away from direct sunlight, extreme temperatures, and corrosive substances. Avoid bending or kinking the hoses during storage, as this can lead to premature wear and deformation.

Regular Cleaning and Maintenance:

Incorporate regular cleaning into your maintenance routine to prevent the buildup of hardened concrete, sediment, and debris inside the hoses. Clean hoses thoroughly after each use using appropriate cleaning methods, such as mechanical cleaning, chemical agents, or high-pressure water jetting. Flushing the hoses with clean water after cleaning helps remove residual cleaning agents and debris.

Proactive Repairs and Replacement:

Address any identified issues or damage promptly to prevent further deterioration and ensure safe operation. Repair minor damage, such as small cracks or leaks, using suitable repair kits or materials. In cases of extensive damage or wear, consider replacing the hoses to maintain optimal performance and safety.

Operator Training and Education:

Provide comprehensive training to operators on the proper handling, usage, and maintenance of concrete pump hoses. Educate personnel on best practices, safety protocols, and manufacturer recommendations to minimize risks and ensure efficient operation. Regularly update training programs to incorporate new technologies and industry standards.

Documentation and Record-Keeping:

Maintain detailed records of maintenance activities, inspections, repairs, and replacements for each concrete pump hose. Documenting maintenance history allows for better tracking of hose condition, performance, and compliance with regulatory requirements. Use digital or physical maintenance logs to record relevant information and track maintenance schedules.

FAQs

How often should I clean concrete pump hoses?

Regular cleaning of concrete pump hoses is recommended after each use to prevent the buildup of hardened concrete and debris.

Can I use bleach for cleaning concrete pump hoses?

Bleach is not recommended for cleaning concrete pump hoses as it can damage the hose material and pose safety hazards. Opt for specialized cleaning agents formulated for concrete removal.

Is it necessary to flush the hose after cleaning?

Yes, flushing the hose with clean water after cleaning is essential to remove any residual cleaning agents or debris and ensure proper operation.

What precautions should I take when cleaning concrete pump hoses?

When cleaning concrete pump hoses, wear appropriate protective gear, such as gloves and safety goggles, and follow manufacturer guidelines for handling cleaning agents.

Can I reuse wastewater from hose cleaning?

Reusing wastewater from hose cleaning is not recommended due to the presence of contaminants and chemicals. Proper disposal methods should be followed to minimize environmental impact.

How can I prevent hose blockages during operation?

To prevent hose blockages during operation, ensure that concrete mixtures are properly proportioned and free of excess aggregates or contaminants. Regular inspection and maintenance of hoses are also crucial for identifying potential blockage risks.

Conclusion

Cleaning concrete pump hoses is essential for maintaining optimal performance and prolonging their lifespan. By following the methods and tips outlined in this guide, you can ensure efficient cleaning practices and minimize the risk of equipment damage. Remember to prioritize safety and environmental considerations throughout the cleaning process.